肯纳碳化钨混合粉

肯纳金属公司提供各种规格的碳化钨混合粉末。精确的质量控制,大批量均匀,高纯度和粒度均匀性增强了其对硬质合金制造商的需求。

肯纳金属公司的大晶热敏工艺为直接从精矿中生产碳化钨晶体提供了一种高效的方法。大晶WC的独特性能在金刚石刀具基体粉体等许多特殊应用中得到了广泛的应用。WC晶体在铁元素中生长到500微米,化学计量单位为6.13%的碳,生成稳定的碳化物,是渗透和磨损应用的理想材料。

特性:

1、全渗碳、致密、高纯碳化钨晶体,由肯纳公司独特、专有的高温“铝热体”反应生产。

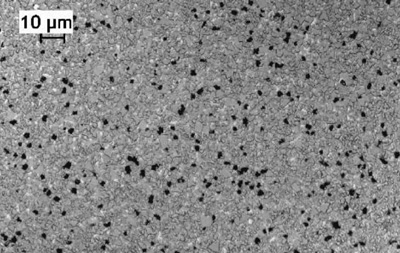

2、主要不含有害的未结合碳。

3、非团聚的单碳化物,可在40美国网(420微米)至1.5微米的粒度。

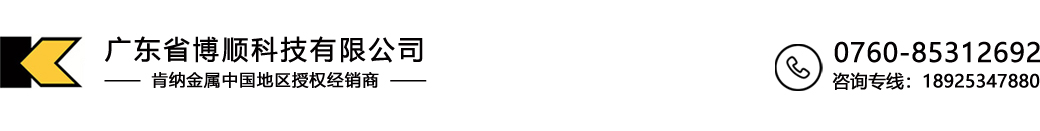

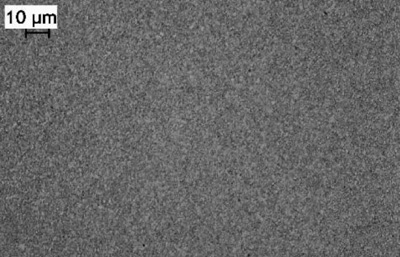

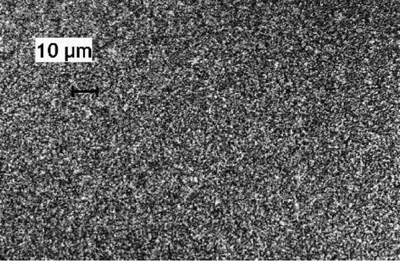

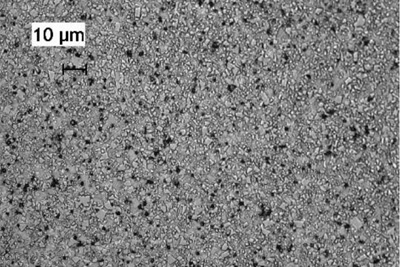

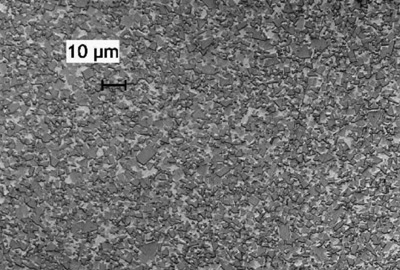

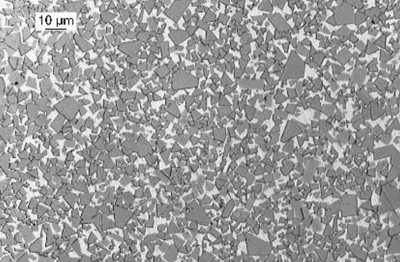

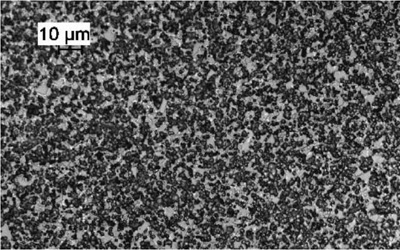

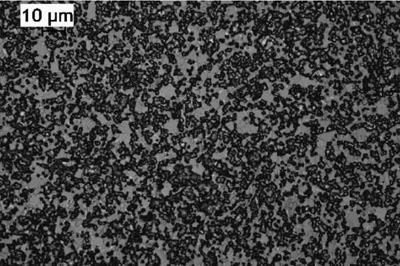

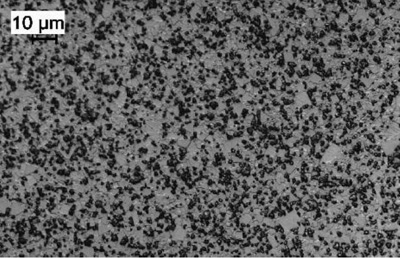

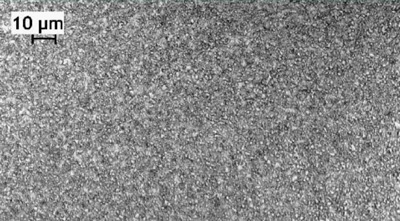

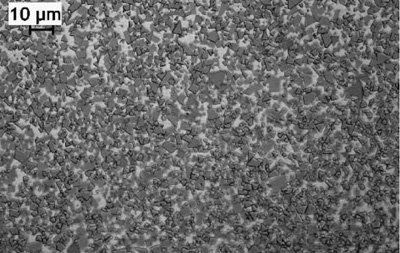

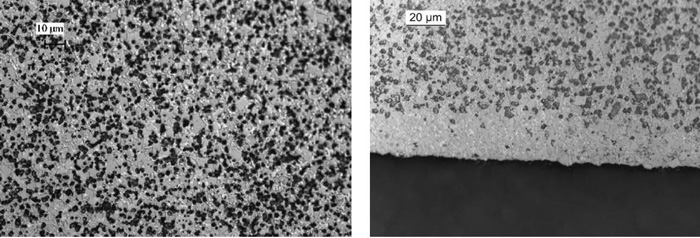

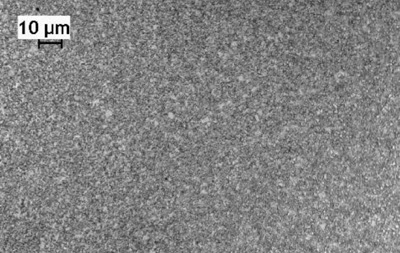

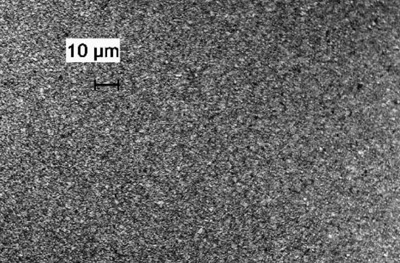

4、定义良好的内部微观结构:由单晶生长而成。均匀性好,重现性好。角晶有三角形的习性。

5、无变子结构:无低渗碳W2C相。

6、在4500°F(2480°C),慢慢地冷却:微缺陷低。较高的显微硬度。

7、比表面积相对较低。

8、烧结过程中晶粒生长缓慢。

9、高润湿性。

10、高包装密度提供了最多的碳化物单位体积。

11、维氏显微硬度VHN (25g)约2200 kg/mm2。

12、优异的性能在采矿等级,磨损零件,堆焊棒,和渗透钻石工具。

13、用于浸润、热压或烧结金刚石工具的理想起始材料。

14、将钴、青铜、铁、镍和其他常见金刚石工具基体混合成均匀的混合物。

15、典型的分析范围:

Total carbon: 6.08%–6.24%

Free carbon: 0.05% maximum

Iron: 0.30% maximum

GWC-1

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 93.0 |

| Co | 6.0 | Density (g/cc) | 14.85 |

| VC | 0.3 | Coercivity (Oe) | 325 |

| Total All Others | <=0.5 | % Magnetic Saturation | 90 |

| Total Wax | 2.2 | Max Porosity | A02,B00-24,C00 |

| Hall Flow (50g) | <=28 sec | ETA Phase | None |

| Scott Density (g/cm^3) | 55 | Precipitated Carbon | None |

| Preferred Sintering Temp. | 1450°C | ||

GWC-5C

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 91 |

| Co | 6.0 | Density (g/cc) | 13.9 |

| VC | 0.3 | Coercivity (Oe) | 250 |

| Cr | 0.4 | % Magnetic Saturation | 90+ |

| Total All Others | <=0.5 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=28 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Preferred Sintering Temp. | 1400°C |

GWC-13

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 92 |

| Co | 6.0 | Density (g/cc) | 14.9 |

| TiC | 0.17 | Coercivity (Oe) | 225 |

| TaC | 0.17 | % Magnetic Saturation | 90+ |

| NbC | 0.17 | Max Porosity | A02,B00-24,C00 |

| Total All Others | <=0.3 | ETA Phase | None |

| Total Wax | 2.2 | Precipitated Carbon | None |

| Hall Flow (50g) | <=28 sec | Preferred Sintering Temp. | 1450°C |

| Scott Density (g/cm^3) | 55 | ||

GWC-15

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 89.7 |

| Co | 11.0 | Density (g/cc) | 14.3 |

| TiC | 0.4 | Coercivity (Oe) | 165 |

| TaC | 0.5 | % Magnetic Saturation | 90 |

| NbC | 0.3 | Max Porosity | A02,B00-24,C00 |

| Total All Others | <=0.4 | ETA Phase | None |

| Total Wax | 2.2 | Precipitated Carbon | None |

| Hall Flow (50g) | <=28 sec | Preferred Sintering Temp. | 1400°C |

| Scott Density (g/cm^3) | 55 | ||

GWC-26

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 88.3 |

| Co | 11.5 | Density (g/cc) | 14.35 |

| Total All Others | <=0.9 | Coercivity (Oe) | 120 |

| Total Wax | 2.2 | % Magnetic Saturation | 90+ |

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 55 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1400°C | ||

GWC-49

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 84.5 |

| Co | 20.0 | Density (g/cc) | 13.6 |

| Total All Others | <=0.7 | Coercivity (Oe) | 80 |

| Total Wax | 2.2 | % Magnetic Saturation | 92 |

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 55 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1375°C | ||

GWC-50

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 86 |

| Co | 15.0 | Density (g/cc) | 14 |

| Total All Others | <=1.0 | Coercivity (Oe) | 80 |

| Total Wax | 2.2 | % Magnetic Saturation | 90 |

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 60 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1400°C | ||

GWC-55

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 84 |

| Co | 18.0 | Density (g/cc) | 13.7 |

| Total All Others | <=0.7 | Coercivity (Oe) | 55 |

| Total Wax | 2.2 | % Magnetic Saturation | 92 |

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 60 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1400°C | ||

GWC-69

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 91.2 |

| Co | 10.0 | Density (g/cc) | 12.2 |

| TiC | 6.5 | Coercivity (Oe) | 160 |

| TaC | 5.05 | % Magnetic Saturation | 90 |

| NbC | 5.05 | Max Porosity | A02,B00-24,C00 |

| Total All Others | <=0.5 | ETA Phase | None |

| Total Wax | 2.2 | Precipitated Carbon | None |

| Hall Flow (50g) | <=28 sec | Preferred Sintering Temp. | 1400°C |

| Scott Density (g/cm^3) | 55 | ||

GWC-70

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 91.4 |

| Co | 8.5 | Density (g/cc) | 12.15 |

| TiC | 8.0 | Coercivity (Oe) | 150 |

| TaC | 4.2 | % Magnetic Saturation | 90 |

| NbC | 4.2 | Max Porosity | A02,B00-24,C00 |

| Total All Others | <=0.5 | ETA Phase | None |

| Total Wax | 2.2 | Precipitated Carbon | None |

| Hall Flow (50g) | <=28 sec | Preferred Sintering Temp. | 1450°C |

| Scott Density (g/cm^3) | 55 | ||

GWC-72

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 91.4 |

| Co | 5.5 | Density (g/cc) | 13.8 |

| TiC | 3.0 | Coercivity (Oe) | 160 |

| TaC | 2.7 | % Magnetic Saturation | 92 |

| NbC | 1.8 | Max Porosity | A02,B00-24,C00 |

| Total All Others | <=0.6 | ETA Phase | None |

| Total Wax | 2.2 | Precipitated Carbon | None |

| Hall Flow (50g) | <=28 sec | Preferred Sintering Temp. | 1450-1475°C |

| Scott Density (g/cm^3) | 55 | ||

GWC-76

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 90 |

| Ni | 10.0 | Density (g/cc) | 14.5 |

| Total All Others | <=0.5 | ||

| Total Wax | 2.2 | ||

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 55 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1450-1475°C | ||

GWC-86

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 83 |

| Co | 25.0 | Density (g/cc) | 13.1 |

| Total All Others | <=0.7 | Coercivity (Oe) | 70 |

| Total Wax | 2.2 | % Magnetic Saturation | 92 |

| Hall Flow (50g) | <=28 sec | Max Porosity | A02,B00-24,C00 |

| Scott Density (g/cm^3) | 52 | ETA Phase | None |

| Precipitated Carbon | None | ||

| Preferred Sintering Temp. | 1375°C | ||

GWC-167

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 92.8 |

| Co | 6.0 | Density (g/cc) | 14.85 |

| VC | 0.2 | Coercivity (Oe) | 300 |

| Cr | 0.3 | % Magnetic Saturation | 92 |

| Total All Others | <=0.5 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=28 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Preferred Sintering Temp. | 1425-1450°C |

GWC-177

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 90.5 |

| Co | 8.5 | Density (g/cc) | 13.55 |

| TiC | 3.0 | Coercivity (Oe) | 135 |

| TaC | 2.7 | Linear Shrink Factor (LSF) | 0.820 |

| NbC | 1.8 | % Magnetic Saturation | 92 |

| Total All Others | <=0.5 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=28 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Enrichment Layer | Yes |

| Preferred Sintering Temp. | 1450°C | ||

GWC-196

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 91.8 |

| Co | 10 | Density (g/cc) | 14.40 |

| VC | <=0.4 | Coercivity (Oe) | 270 |

| Cr | <=0.6 | % Magnetic Saturation | 92 |

| Total All Others | <=0.4 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=25 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Preferred Sintering Temp. | 1400°C |

GWC-203

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 92.5 |

| Co | 12 | Density (g/cc) | 14.15 |

| VC | 0.3 | Coercivity (Oe) | 380 |

| Cr | 0.5 | % Magnetic Saturation | 90+ |

| Total All Others | <=0.5 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=28 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Preferred Sintering Temp. | 1400°C |

GWC-210

Product Specification:

| Chemical Composition Targets (Weight %) | Metallurgical Property Targets | ||

|---|---|---|---|

| WC | Balance | Hardness RA | 89.5 |

| Co | 11.0 | Density (g/cc) | 14.3 |

| TiC | 0.15 | Coercivity (Oe) | 145 |

| TaC | 0.7 | Linear Shrink Factor (LSF) | 0.826 |

| NbC | 0.7 | % Magnetic Saturation | 90 |

| Total All Others | <=0.5 | Max Porosity | A02,B00-24,C00 |

| Total Wax | 2.2 | ETA Phase | None |

| Hall Flow (50g) | <=28 sec | Precipitated Carbon | None |

| Scott Density (g/cm^3) | 55 | Preferred Sintering Temp. | 1400°C |